How In Fill Panels can Save You Time, Stress, and Money.

Table of ContentsNot known Details About In Fill Panels How In Fill Panels can Save You Time, Stress, and Money.The 4-Minute Rule for In Fill PanelsNot known Incorrect Statements About In Fill Panels

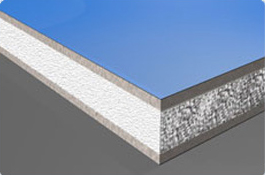

Infill wall surfaces are generally set up on site as individual aspects that are pre-cut to size but they can be pre-fabricated as big panels with the cladding already connected (in fill panels). The same components may be made use of for interior separating walls, yet below the primary problems are fire resistance and also acoustic insulation as opposed to resistance to.loading. A nominal interior stress is used in the layout of internal separating walls. @&&h2@ [leading]

Sorts of

The Single Strategy To Use For In Fill Panels

infill walling @&&/h2@ Different kinds of construction can be used to produce infill wall surfaces that extend between floorings in steel or concrete structures. Traditionally, infill walls made use of masonry or timber, however the contemporary type of construction uses light steel C sections that period between the floorings as well as around openings. The C areas are put at a normal spacing relying on the outside faade materials, and at a spacing which is additionally compatible with standard plasterboard as well as sheathing board dimensions. @&&h3@ [top]

Light steel framed infill wall surfaces @&&/h3@ In multi-storey mounted construction, it is now common method to make use of light steel infill walls to create a rapid completely dry envelope to sustain the exterior cladding. The same type of building and construction might be used as dividing or compartment wall surfaces between various parts of the building. Using light steel infill wall surfaces might be related to steel or concrete framed building. Lightweight, speed and also simplicity of installation are essential constructional benefits that have caused the quick boost being used of this form of construction.

The light steel parts utilized in infill wall surfaces contains C sections and also U areas of.

The 6-Minute Rule for In Fill Panels

75 to 150 mm depth that are cool roll-formed from galvanized steel strip of 1. 2 mm thickness specified to BS EN 10346. The galvanizing( zinc layer) provides excellent durability. The C areas are placed at 400 or 600mm spacing as well as sets of C sections might be made use of beside huge openings. Wall panels can be pre-fabricated as storey-high systems or, more frequently, are website put together from C sections that are provided cut-to-length. The second method is usually the only option in renovation applications where resistances in the initial building have actually to be accommodated. Site put together light steel wall surfaces in a steel mounted structure Pre-fabricated light steel infill wall panels in a steel mounted structure Infill walls are composed of a bottom' track' connected to the floor as well as a top' track' affixed to the underside of the flooring above. This movement is essential in concrete frames, where 2 to 3 mm reducing of the concrete framework per flooring can occur in time in addition to typical structural motions. The vertical C areas are designed to cover 2. 4 to 5m between floorings, and also to withstand wind loads or other loads in flexing. The straight C areas over as well as below the home windows transfer loads back to the upright C sections. 1 or 2 layers of' fire-resistant' plasterboard( adapting BS EN 520, Type F) to the internal face offer up to 90 mins fire resistance to the light steel infill wall surface. @&&h3@ [leading] Light steel separating wall surfaces @&&/h3@ Pre-fabricated light steel wall surface panels Light you can find out more steel separating wall surfaces use comparable parts to.

light steel infill wall surfaces and are utilized to offer acoustic splitting up and fire compartmentation in between occupancies or distinct parts of the structure. For both of these functions, dual layers wall surfaces are generally defined in order to accomplish the required acoustic depletion in between occupancies. The architectural loading for interior walls is reasonably reduced as well as is typically considered to correspond to an interior pressure of 0. 5 k, N/m . The C sections are typically much thinner than in exterior walls( usually 0. 9mm thick )and gain some benefit of the tightness of the plasterboard chosen the outside. Dividings are not needed to have.

acoustic or fire features therefore are solitary leaf wall surfaces making up C sections of 55 to. in fill panels.

The Buzz on In Fill Panels

90mm depth, relying on the wall surface elevation, with single layers of plasterboard on each side. @&&h3@ [top] Stonework infill wall surfaces @ & &/ h3 @. Wall surfaces created from clay bricks or cinder block are the typical form of infill wall construction. Nonetheless, the usage of block-work infill wall surfaces has reduced recently because it is an untidy and also time consuming site operation, and needs a big amount of products dealing with. From a design perspective, enhancing blog posts are required alongside huge window openings, as the stonework is not sufficiently solid to resist the high regional wind loads beside find more these openings. @&&h3@ [leading] Concrete infill walls @&&/h3@ Pre-cast concrete infill wall surface panels Concrete infill wall surfaces are typically in the kind of big precast concrete panels that are storey high and also usually of a size dictated by the column spacing. These huge panels might be leading hung or lower sustained. They generally birth onto the floor slab

making use of a boot plan, and also are bolted back to the structure on the degree over or listed below. Indispensable panels might be outfitted in various other materials( generally concrete panels are outfitted in rock) - in fill panels. Panel weights of approximately 300kg/m are common, with panel sizes of in between 3 as well as 9m and elevation of 3. 2m. The optimum dimension of panel is limited by transport factors to consider and crane lifting capability( both on website as well as at the concrete jobs). 15 to 20 tonnes are common optimum weights of precast concrete panels. @&&h3@ [top]. Hardwood mounted infill walls @&&/h3@ Lumber infill walls make use of common hardwood areas of 90.

and also 140mm deepness to span 2. 4 to 3. 6m between floorings as site web well as are similar in type to light steel infill wall surfaces. Timber sections are reduced to size as well as are placed at 400 mm or 600 mm spacing. The negative aspect of hardwood in contrast to steel is that it is not as strong and it is not feasible to use it in high walls or in wall surfaces with large openings. @&&h2@ [top] Advantages of light steel infill as well as separating walls @&&/h2@